One of the best ways for a business to serve its customers in a better way is to design effective supply chain management as a strategic priority.

In general, supply chain management is the activity of overseeing all supplier integration processes so that they work efficiently in moving products from manufacture to reaching customers, taking into account supply and demand.

In this article, we will discuss what is it and its elements.

What is a Supply Chain?

The supply chain includes all the activities, people, organizations, information, and resources needed to move a product from the point of origin to the customer. In the case of consumer goods, this process includes raw materials, production, packaging, shipping, warehousing, and retail.

Actually, the goal is very simple, to meet customer demands, but the process is very complicated and involves many parties.

The supply chain can add value to all industries, which is why it must be an important component of business strategy.

What is Supply Chain Management?

Supply chain management is the process of integrating supply and demand management, not only within the organization but also across all aspects of the supply chain channel so that all can work together effectively and efficiently.

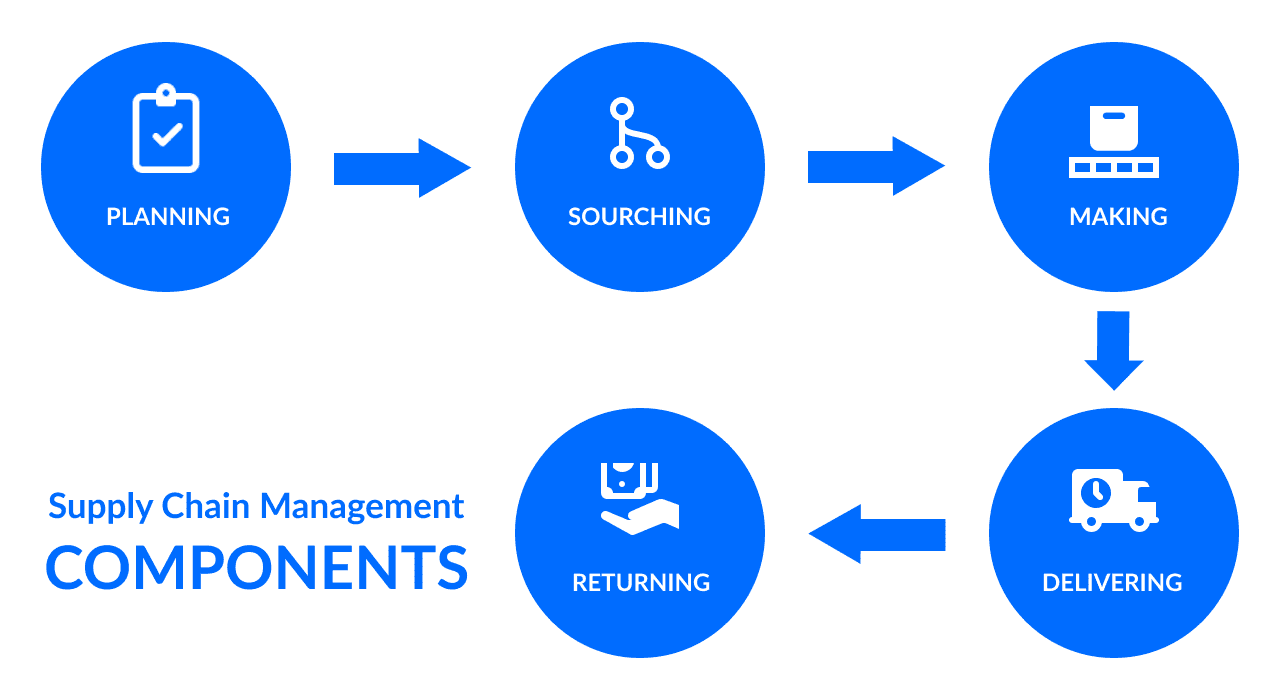

Supply Chain Management Components

There are five basic components in supply chain management:

1. Planning.

To meet customer demand, supply chain managers must plan forecasting demand, designing supply chains, and determining how the company will measure whether the supply chain is meeting expectations in terms of efficiency, providing value to customers, and helping achieve company goals.

2. Sourcing.

Selecting suppliers who will provide goods, raw materials, or services to create a product is an important component of the supply chain. Not only contracting vendors but also managing and monitoring existing relationships. As part of strategic sourcing, supply chain managers must oversee the process of ordering, receiving, managing inventory, and authorizing invoice payments for all vendors.

3. Making.

The supply chain manager also has to help coordinate all the steps involved in the process of creating a product. This includes reviewing and receiving raw materials, manufacturing products, quality testing, and packaging. In general, the company will evaluate the quality of production and employee productivity to ensure that the overall standards are appropriate and well implemented.

4. Deliveries.

Ensuring products are received by customers through logistics services is a critical part of the supply chain. Such as managing orders, scheduling deliveries, shipping, creating invoices, and receiving payments.

Most companies outsource the delivery process to the third-party logistics company. Such as SCN Logistics Group, which provides integrated logistics services and is able to provide more efficient logistics services.

5. Returns.

Supply chain managers also need to develop networks to support product returns. In some cases, this includes disposing of or re-manufacturing defective products. But in other cases, it is only a product return by the customer.

Benefits of Supply Chain Management for Companies

Effective supply chain management provides three main benefits for a company. Here are some of the benefits that will be obtained:

1. Lowering Costs.

By integrating suppliers using technology, companies can lower operating costs by responding to customer needs dynamically. Managing inventory on demand keeps organizations from over-producing, not only reducing labor and raw material costs but also reducing inventory management costs and transportation costs.

2. Increase Income.

When a company uses technology to respond to customer requests, it is more likely that product stock will remain available for purchase. In a leaner manufacturing process, labor and raw materials can be used to develop new products to offer customers. Outside of product manufacturing, this section may mean offering additional services to customers.

3. Maximum Utilization of Assets.

With good supply chain management, companies can use assets such as production equipment or transportation effectively. Instead of reducing the value of manufacturing equipment to unnecessary things, companies can manufacture products as needed.

It allows a company to control product stock, reduce quality problems, deliver products more quickly to customers, and control product returns properly, so as to increase the value of the company’s products and services.

What is the Difference between Supply Chain Management and Logistics?

When we talk about logistics and supply chain management, the two things are indeed “similar but not the same”.

Logistics refers to the movement and storage of products inside and outside the company. While supply chain management is a series of interrelated activities related to the manufacture and movement of products from raw materials, finished products to the hands of customers.

Please read the full discussion of logistics in the article what is logistics and how does it work?

Visit SCN Logistics Group’s Facebook, Instagram, Linkedin, and Youtube pages to get information about logistics and logistics services.

Add a Comment

You must be logged in to post a comment